The official version of this document can be found via the PDF button.

The below content has been automatically generated from the original PDF and some formatting may have been lost, therefore it should not be relied upon to extract citations or propose amendments.

SEVENTH FRAMEWORK PROGRAMME THEME

Research for SMEs – Call 1

Grant agreement for: Research for the benefit of specific groups (in particular SMEs)

![]() DELIVERABLE for SUDEVAB – 222156

DELIVERABLE for SUDEVAB – 222156

Deliverable Title: Abalone Hygiene and Food Safety, Operational Guidelines Deliverable Number: D 3.4

Project Partner Responsible for Deliverable: JSFI

Project Partner Number: 4

Nature of Deliverable: R

Dissemination Level for Deliverable: PU

Please indicate the nature of the deliverable using one of the following codes: R = Report, P = Prototype, D = Demonstrator, O = Other

Please indicate the dissemination level using one of the following codes:

PU = Public

PP = Restricted to other programme participants (including the Commission Services).

RE = Restricted to a group specified by the consortium (including the Commission Services). CO = Confidential, only for members of the consortium (including the Commission Services).

Reporting Background

Task 3; To develop and disseminate protocols and documentation that creates and industry standard .

Deliverable 3.3.Final Report on research results. Recommendation ;

The documentary and research evidence drawn together by this SUDEVAB work package,gives strong data to back up the generally accepted view that gastropods and that includes The European Abalone (ormer) Haliotis tuberculata. are substantially less of a consumption risk than filter feeding bivalves. An inconsistency exists in the practical application of the relevant Directives (EC852/3/4 2004) ranging from end-product testing only(which may be currently an incorrect interpretation when related to farmed fish but is a workable outcome none the less), through the application of Designated Shellfish Harvesting Areas derived from filter feeding bivalves which give a higher than needed risk analysis, to a separation of gastropods etc as a lower risk class within a set Designated Harvesting Area (the French experience).

It is therefore suggested that the French model of separation of classes of molluscs on a basis of risk from within the same Designated Shellfish Harvesting Area is a demonstrably practical and workable approach and should be adopted in the short term by other authorities on receipt of an application from prospective abalone farmers. Further, consideration should be given to allowing end product testing as the approved microbiological risk strategy for future legislation as has already been indicated as possible and desirable by the UK competent authority representative.

PART 1.

GENERAL BACKGROUND.

The SUDEVAB project relates expressly to the sustainable development of the aquaculture of the European Abalone Haliotis tuberculata (Ormer)in open seawater conditions. This is in contrast to the recirculation or semirecirculation systems that exist or are approaching completion. The reason for this contrast is , that in most cases , the recirculation systems also culture The Ezo Abalone Haliotis discus-hanni , in some cases feed with artificial feed that is in part fish or animal derived, and they can treat by UV or similar, input and output waters.

As the environment in which open seawater Ormers are cultured is beyond the control of the farmer a different approach to the identifying risks involved in the ultimate consumption of the product should apply.The microbiological hazards associated with the consumption of abalone fall into three distinct categories:

- Human pathogens derived from faecal contamination of the marine environment.

- Human pathogens naturally occuring in the marine environment.

- Human pathogens contaminating the product after harvest.

There are, however, other possible approaches at play that make the situation less clear.

- Ormers are gastropods , as are winkles and whelks for instance. In Europe gastropods are almost exclusively allocated end-product quality criteria for placing on the marketplace for consumption (EC852/2004)(Annex I.). (source CEFAS).If ormers are fished for rather than farmed then this end-product quality must apply alone.

- EC 853/2004 (Annex I)on the other hand defines Ormers (abalones) as with tunicates, echinoderms and other gastropods as by analogy bivalves and in the farmed context requires them to be reared from a Designated Shellfish Harvesting Area with that area having a classification A/B/C relating to E.coli levels etc in the farmed species.

- There is a consensus developing that gastropods should be de-coupled from bivalves in future EC legislation and that they should require just end product testing irrespective of the source (farmed/wild).

- The FAO are near to completing a Draft Standard for Live Abalone and for raw/fresh/chilled or frozen Abalone for direct consumption or for further processing'(Annex II). This to a large extent mirrors the EC existing approach based

on quality standards and does not move the game forwards' towards risk analysis in a way that is analogous to the Animal Health Directive (Aquaculture Products) EC 2006/88 does with regards to animal diseases , for instance. In this legislation more onus is put on the producer to take responsibility, based on information and links scientific vector information, susceptibility and farmed context . A Risk Analsysis approach to hygiene could be seen to have significant advantages but would require knowledgable and sophisticated producers.

- Current Designated Shellfish Harvesting Areas and End Product criteria are based on indicator organisms (Ecoli etc) rather than actual high risk organisms such as Norovirus. Again there is a strong desire to attain norovirus standards and remediation processes which may entirely change the way shellfish producers operate.

- New issues may arise such as Vibrio parahaemoliticus . This is a major problem worldwide but not as yet in Europe , but it has in the last few years been isolated in European waters.

- Biotoxins have not been regarded as a substantive risk for abalone production in Europe but that may not be case. Since the commencement of the project an area of fished Ormers in Galacia (Spain) has had a closure order due to biotoxin levels, and an argument between the FAO Codex correspondents has arisen regarding inclusion of biotoxin testing when the known occurances were isolated ones in South Africa and South America.

- There are differing approaches to classification of gastropod , therefore inculding abalone, production areas in Europe; (Source CEFAS )

The United Kingdom. The classification of gastropod has not been historically undertaken in the UK. This was for a number of reasons, primarily due to bivalve molluscs being deemed to represent a significantly higher risk.However, in September 2005 an abalone farm in Cornwall was classified as Grade A ( suitable for immediate consumption). It is no longer commercially active and has been declassified.

Belgium. There is only one classified area in Belgium and that is for Ostrea edulis The Flat Oyster and Crassostrea gigas The Pacific Oyster.Gastropods are harvested from outside the classified area.

Denmark. Various species of bivalves are classified but no gastropods. No information is available as to whether gastropods are harvested in Danish waters.

France. In 2006, there were 103 classified areas for shellfish in the French Classification 1. (gastropods,tunicates and echinoderms). 99 Grade A, 3 Grade B, and 1 C area.All of those areas were classified by the local administration without any physical survey of the shoreline area and without any microbiological results (one or two exceptions).Most of the areas, often situated in deep sea or open ocean are not commercially exploited.The reason given for not sampling gastropods is stated to be the difficulty of extracting flesh. However, ISO 6887-3 does contain methods for the preparation of gastropod samples for microbiological examination.

Germany. Germany has classified areas for oysters and mussels but not gastropods. There is no information as to whether gastropods are harvested in German waters.

Italy. Italy has classified areas for a wide range of bivalve molluscs but not for gastropods despite having fisheries for them.

Spain. Some details are available for Galacia. The total production of gastropods in 2006 was 15.2 Tonnes. There are 30 zones classified on a provisional basis. These comprise 26 Class A, 2 Class B and 2 Class C zones.

Portugal. Classification only covers bivalves but gastropods are harvested for consumption.

Ireland. There are classified areas for bivalves and echinoderms but not gastropods despite having a large periwinkle industry.

It is within this uncertain, variable and changing hygiene environment that this Work Package will seek to give , if not clarity, then options for prospective Ormer farmers in open seawater with regard to their final product sales.

Although the process of Risk Analysis is not yet the requirement for achieving a saleable product it assists in generating logical steps to the desired end of safe abalone consumption through the steps of Risk Assessment – Risk Management - Risk Communication , and can be incorporated into farm management systems at an early stage.

What are the risks presented by abalone consumption?

Little hard data exists for abalone consumption risk but some does exist for general shellfish risk Table 1 Column 1 lists the specified pathogens contained in current legislation and codices, this can then be sub-divided into ,What are the actual rates of disease relating to specific causative agents ,in a European context, associated with the consumption of molluscs and by inference abalone? Fortunately this exists in Extended Europe 1993-98 Epidemiological Data (WHO ,2001) .

Hazard Identification Causative Agent | Hazard Characterization Based on reported molluscan derived events 1993-1998 (WHO 2001) | Exposure Assessment Relating to Abalone | Mandatory Levels EC/Codex | ||

Salmonella spp total | 77.1% | Mostly related to kitchen based contamination | Nil in 25g | ||

Other pathogenic Bacteria Staphylococcus aureus Shigella spp Clostridium botulinum V.parahaemolyticus E.coli E.coli 0-157 | Handling risk Processing risk Unknown in abalone SUDEVAB research Not known to be present in seawater | Nil Nil Nil Probably Nil <230/100g | |||

4.1% 2.7% 1.0% 0.1% 0.7% 0.2% |

|

| |||

Viruses Virus (not identified) Norwalk Type Calici virus Rotavirus Hepatitis A | Possibly new standards for molluscs SUDEVAB RESEARCH Current CEFAS research Only recorded in European shellfish 3 times 2000-8 | Unspecified at Present but likely in the very near future | |||

0.2% 0.1% 0.1% 0.1% 0.2% |

|

| |||

Chemical and Physical Substances | 0.4% | Primarily processing risk | Usually absence | ||

Biotoxins DSP PSP AZP Yessotoxins | Conflicting information But some European DSP suspected evidence | Saxitoxin 0.8mg/kg OAO 16mg/kg DA 20mg/kg Brevetoxin 20MU AZP 0.16mg/kg | |||

|

|

| |||

Table 1.

There are structured routes that are internationally recognised to generate a Risk Assessment as follows;

Hazard characterisation .The qualitative and/or quantitative evaluation of the nature of the adverse health effects associated with the hazard.

Exposure assessment.The qualitative and/or quantitative evaluation of the likely intake of biological,chemical and physical agents via abalone.

Risk characterisation.Generating a Risk estimate by determining qualitative and/or quantitative estimation, including attendant uncertainties, of the probability of occurence and severity of known or potential adverse health effects in a given population .leading to a Risk Assessment

Taking Table 1 figures for molluscs hazard the abalone hazards can be derived by inference and common parameters.

Salmonella . Majority of salmonella( salmonellosis rather than S.typhi Typhoid ) infections are caused by domestic/catering issues and constitute the highest risk factor (77.1%) . It is possible for abalone to transmit salmonella as the organism is persistent in theenvironment but there are no records available of this happening.The mandatory levels in the EC rules and Codex is ,no presence in 25g. In practice with a designated shellfish harvesting area this is usually done annually (within a monthly testing regime )if there is no specific risk noted.

If abalone are eviscerated ,cleaned and cooked correctly this should be a zero level risk, but it is always possible for end users to undercook, underprepare or in the case of a Japenese delicacy ,ferment the digestive glands in rice wine (saki) and drink them raw.

What action can an abalone farmer take to mitigate this risk ? Depending on the testing regime applied (addressed in chapter 3) abalone should be tested periodically within a structured assessment . If a positive result is detected, the only solution is to cease processing recall any risk product and await clear testing.

It should be noted that no depuration processes exist for abalone for any of the listed risk factors and some evidence exists that they may not work at all (See Annex (Ethridge et.al))

Other pathogenic bacteria. These fall into three categories .The first contains Staphyloccus aureus and Clostridum botulinum. These are both process risk organisms or toxin. With Staph.aureus this is due to handling issues as it is usually present in skin and mucous membranes and can be overcome by the use of nitrile catering gloves when handling and processing (see HACCP in Chapter 4). This organism should not be present and should be tested for as part of an end product quality regime if processing is being undertaken. Clostridium botulinum which is usually present in soils and sediments is a potentially fatal toxin producer thatis heat resistant and requires anoxic conditions to develop, good hygiene practice and a HACCP will prevent these conditions from being present.Shigella sp. There have been recordings of outbreaks of shigellosis related to sewage pollution and handling (Hackney et al. 1992) but there is little data to back this up or comment on how to avoid it other than the general hygine procedures and testing regimes using indicator organisms.

Secondly Vibrio parahaemolyticus this is a common bacterial infection in some parts of the world often estuaries where the population eat large quantities of seafood.This bacterium may well be a natural inhabitant of both polluted and unpolluted seawater. Only a few isolates appear pathogenic to humans, however the Codex is suggesting specific levels of testing without specifing pathogenicity, fortunately the EC853 does not comment on this organism. Other favourable issues are that it is low temperature intolerant and is rarely found at water temperatures below 8-10C (Baross and liston 1970) this represents a normal winter sea temperature for European abalone culture in open seawater. Negatively there are reports of detection in the English Channel in 2009 (A.Fitzgerald pers.comm.)

Finally Escherichia coli and faecal coliforms. This is the primary indicator organism of sewage pollution. Specific levels of E.coli in shellfish are given in EC 852 and EC 853 and elsewhere. In Ch 5 the Sudevab research on the relative uptake of this indicator organism by abalone, oysters and mussels in both real production areas and controlled laboratory conditions is given. Taking the Designated Shellfish Harvesting criteria of Category A, less than 230 Ecoli from 100g tested by the MPN method, as the target for abalone production ,can this be achieved in waters used for other shellfish that might themselves record up to 4600 Ecoli as the upper boundary for Category B. The reason for this approach is related to depuration or relaying issues. If the counts exceed 230 Ecoli then the shellfish must be depurated in an approved manner or relayed in a Category A, for abalone this is unproven and probably unachievable this then means that abalone must be reared in waters that give less than 230Ecoli 100g recording for those abalone. From a practical application and the primary function of this document arises the question' What is a safe level of Ecoli contamination as an indicator species in abalone and what is the mandatory level required?'

The firm answer is that sampling should not exceed 230 Ecoli/100g in all samples.The work of Sudevab has helped to clarify how achievable that is . Put crudely it should be expected that if a category A site for oysters is used for abalone then the expected upper boundary for Ecoli in abalone when it records 230 in oysters , should be in the region of 40 Ecoli 100g .That means that abalone are likely to be much safer than oysters even in an oyster safe area.The issue may then arise, what if the Category for oysters has already been established as B ?, this creates an issue whereby the Designated Harvesting Area has already been determined and the abalone must be relayed or depurated, which does not work.Although the abalone will probably be below the 230 level even when the oysters attain the upper boundary of 4600 the classification and depuration requirements would stand.

The consequences of this would be open to local interpretation to some extent but it would appear that the safe course of action and the appropriate risk analysis would involve obtaining a Designated Shellfish Harvesting Area for abalone alone. This is covered in detail in ChX

The fundamental element regarding Ecoli as an indicator species, and specification that less than 230 Ecoli/100g in abalone is safe for direct consumption is easily achieved in most open sea areas even if in comparable areas oysters for instance would require depuration.

Norovirus.Norovirus also known as Norwalk/Norwalk-like viruses are a gastroentestinal illness causing organism that is transmitted by numerous means including shellfish.The incidence can often be seasonal with winter periods showing the highest illness events. A significant effort is currently underway to establish this organism as a monitoring species for shellfish contamination.

EC 2073/2009 states (27)." In particular, criteria for pathogenic viruses in live bivalve molluscs (abalone by inference) should be established when the analytic methods are developed sufficently".

Because of this the Sudevab WP3 was adapted to include comparison of uptake of norovirus between abalone,oysters and mussels. The result in Part 2 was that abalone were much slower at absorbtion and did so at a level at least two orders of magnitude (1/100) of that in oysters.

Consequently the risk assessment for this contaminant places abalone at a much lower risk than bivalves and should or when the monitoring criteria changes to norovirus then it is unlikely to be problematic .

Hepatitis A. Is one of the most serious viral diseases .Although sewage pollution is an important source , viral concentrations do not show a close association with faecal bacterial indicators. This is due to the relative survival of viruses through secondary and tertiary sewage treatment as compared to bacterial indicator species. There are no methods available to the abalone farmer to manage this risk other than the Designated Shellfish Harvesting criteria or End Product Standards.

Marine Biotoxins. The Designated Shellfish Harvesting Area and End Product criteria specify which biotoxins derived from marine organisms are considered and the mandatory levels that apply. The relevance to abalone in a European situations is uncertain.It is not known for certain that European Abalone concentrate biotoxins , one incident in Galacia raised suggestions that they may preferentially concentrate these toxins in the pigmented epithelia as a defence mechanism, but this has not achieved scientific recognition. Other species in the Southern Hemisphere (South Africa and Chile) are susceptible and suffer occasional fisheries closures . However, during the drafting of the Codex New Zealand, EU and other bodies have pushed to have biotoxins removed from test criteria.As such the risk assessment relating to biotoxins for a European Abalone farmer has to relate to the mandatory quality standards.

Risk Analysis Summary.

As a producer of high quality shellfish ,the European abalone farmer must not only comply with mandatory quality criteria but in order to maintain customer confidence and acceptibility of the product , ensure that maximum food safety is achieved. Fortunately ,with abalone , this is easier than with bivalves. The SUDEVAB reserach has shown that in comparable real and laboratory conditions , abalone concentrate indicator organisms (Ecoli) at an average of 8% of that by cohabiting oysters and 1% when challenged in laboratory conditions by a known norovirus standard.

Fundamentally, abalone are a very safe shellfish to consume . Any future change in legislation regarding monitoring organisms is likely to re-inforce that position.

Establishing as Sea Based Abalone farm in Europe; The hygiene perspective.

The situation regarding compliance is currently clear , that harvesting must come from a classified area, but also there is a strong desire for this to change with regard to gastropods.

In January 2009 Dr.Kevin Hargin, Head of Fish and Shellfish Hygiene, Food Standards Agency , London, was asked about the status of establishing an abalone farm in the UK , his response was;

"As far as the situation with the classification of gastropods harvesting areas is concerned, the legal position remains that gastropods (and tunicates and echinoderms) need to comply with the same conditions as bivalve molluscs and therefore can only be harvested from classified areas. I mentioned at the recent SAGB (Shellfish Association of Great Britain) Mollusc Committee meeting that the European Commission has recently indicated that it is prepared to review this position with regards to gastropods.This process is still very much in the early stages but indications are that Member States (at least those with gastropod harvesting areas) are willing and keen for this situation to be reviewed and clarified.My personal opinion is that there would be reasonable support for a change in the regulations to allow in the future at least non-filter feeding gastropods to be harvested from non-classified areas and controls to be based on end-product testing, though I cannot guarantee such an outcome.The UK would support such a move on the basis that risk assessment appears to indicate a lower level of risk from non-filter feeding gastropods than bivalve molluscs."

It is quite feasible that by the time a new abalone farming unit comes on stream that it will be required to undertake end product testing and the monitoring organism will be norovirus. But that is not currently the case .

Any current farm will have a set of options, if it is within a currently attributed designated shellfish harvesting area then it would be obliged to take that current category , if it is an entirely new area(which in reality is the most probable case) then the criteria specified in (Annex III) Microbial Monitoring of Bivalve Mollusc Harvesting Areas (May 2006) would apply. In summary a monthly set of samples using 12-18 abalone of full size would be taken and analysed using the standardised procedure and at the end of that procedure a provisional classification would be attached.

Precisely this process has been applied to a prospective farm in Portkerris, Cornwall ,England in 2008 and a Classification A was arrived at(and has now lapsed due to non production), but this is not always the case as can be seen from two other examples.

1.Jersey Sea Farms This is a multi species farm based on the East coast of Jersey , a largely self-governing island in the Bay of Mont St.Michel jn the English Channel. The competent authority is The States of Jersey Veterinary Officer who relies on CEFAS as the UK relevant authority for technical advice. As this site has been sampled for oysters for consumption for some years and on a monthly basis (see attached classification) it has a B classification. The interpretation of this is that all bivalves (and therefore gastropods ,tunicates and echinoderms ) coming from this site will require depuration or relaying, as commented earlier this is not a practial or technologically valid option. Consequently the modest numbers of abalone coming from this site are being used for research purposes only. A larger cohort is being reared but these are still some 30 months from being marketable. It is the intention of this producer to use the research data derived from this research package to inform the authorities of the risk levels given by abalone before that time and this may generate options;the entire consideration of gastropod hygiene could turn to end-product testing, the pragmatism of the French authorities (see next paragraph) could be adopted or the current interpretation prevails and in order to sell the abalone the oysters would be discontinued and a year testing for abalone alone undertaken.From a business confidence level this uncertainty is not a positive factor.

2.France Haliotis , L'Aber Wrac'H Finistere France.This company is already producing abalones for consumption. Following a year of sampling from September 2007 a Category A was attained . There are however some significant differences to the Jersey Sea Farms situation,the French authorities split molluscs into three classes I . Gastropods ,Tiunicates,Echinoderms II Bivalves such as clams that use a substrate and III Oyster type bivalves. With this demarcation one site could theoretically have three separate classifications attributed to the different classes. The relevant documentation is attached in Anex IV.

It is therefore demonstrable that within one body of legislation different authorities can interpret differently or at least with different emphasis. This aspect does have significant commercial ramifications and a consistent Europe wide approach based on end-product testing would be the producers chosen path, and it is suggested,would represent a safe production of abalone for consumption.

Photo 1.Manually grading ormers , note the use of gloves, the containers are flushed by clean seawater and this also cushions dropping them into the sort trays.These trays are lined with fresh onion sacking to prevent adhesion and additional stress when they are removed.

Abalone production premises. The legal requirements.

The time scale between establishing an abalone farm and selling product for consumption is at least three and probably four years but , as with many other factors having an approved premises (Despatch Centre) or at least access to one is fundamental.

The regulations that apply are attached in the Annex and can be summarised as follows. 852/2004 Relates to general food hygiene.

2073/2005 Relates to microbiological standards in food.

1881/2006 Creates mandatory levels of contaminats in food.

853/2004 Relates to foodstuff derived from animals

178/2002 Regulates general food quality requirements.

2076/2005 and 2074/2005 slightly modify the above regulations.

Before a despatch licence can be granted , an aproval inspection is required and these are followed up on a routine basis.

These usually follow a check-list approach . In the case of a French establishment it is as follows.

A.Building

Is the building in generally good repair and free of defects.

Is it wind and water tight.

Is it free of vermin ( does a contractural control process exist). Is it being maintained.

Is there adequate airflow, is condensation being managed.

Is the temperature adequate .(both high and low)

Are the pumped water systems adequate and effective especially with regard to the water systems used to contain abalone before despatch.

Is lighting adequate. B. Equipment

Are hand washing facilities adequate.

Are there systems of cleaning and disinfection.

Is equipment kept away from the abalone clean and functioning. Is equipment in contact with the abalone clean and functioning.

In an abalone despatch facility an external tank for separate storage would often exist and this would be commented upon and investigated.

C Personnel

Is personal hygiene adequate

Are personnel adequately trained in the HACCP plan . Are they aware of the site specific requirements. D. Product. What are the sources of the abalone

Do transport documents carry the required information. Do the abalone comply with health certification.

Are there any dangers relating to the product.

Is wash water and ice microbiologically compliant.( It should be noted that both potable water and clean seawater can be used see 853/2004)

E.Functionality

Are cleaning and disinfection procedures being carried out.

Are clean processes and events recorded.

Are there reception and despatch controls and monitoring.

Is handling hygiene by staff understood and adressed.

Is packaging stored and handled in an hygeinic manner.

Is the process by which dangerous organisms or material could develop understood by staff. Is there consistency in the packaging and display of the products.

Is there awareness of CCP Critical Control Points and the corrective actions available and required.

Are there responses to sanitary events.ie communication with authorities following third party sewage discharges outside of normal conditions.

Is the abalone water sufficently aerated.

Do the open sea water pumps contain filters and UV systems and are these monitored and maintained.

Is full tracability of the abalones maintained. F. Documentation.

Are all the formal documents present and held for inspection. G.The Master Sanitary Plan.

Is there an agreed document showing the layout of the sites and the seabased production areas.

Is there an animal/pest exclusion policy and practice.

Are there cleaning and maintenance plans and recording ability.

Are there personal hygiene protocols and are the communicated and recorded. Are personnel medical certificates retained.

Are water quality documents retained.

Are procedures in place to trace and recall produts if required.

Are conformation documents presented on the receipt of product retained and are external risk communications recieved and retained.

Is the HACCP plan available.*

*The writing of a HACCP plan (Hazard Analysis Critical Control Points) will be specific to the operator and a pro-forma one may not allow the operator to scrutinise their own operation fully, identifying risk points (CP ) and providing response and resolution to those points.Consequently Annex VI contains some useful and relevant HACCP process guides from around the world that will help in generating a site specific HACCP.

.

PART 2.

Research Elements

The SUDEVAB WP3 research elements were designed to reflect actual production sites as much as possible and provide hard data to answer the question; How do abalone compare with bivalves in concentrating water borne microbial contaminants?

The first approach was to use existing sites with the ability to rear market sized abalone and other shellfish in actual production situations. The aim was to use existing Designated Shellfish Harvesting monitoring procedures and laboratories to generate comparitive charting of E.coli levels back to back with oysters and mussels over a full year cycle. Two sites were available;

- Jersey Sea Farms , Green Island Site, Oysters Crassostrea gigas. Abalone and MusselsThis is an open water site with a long history of sampling, despite tertiary sewage treatment the oyster samples can exceed 6000 E.coli 100g but in the main remain in the 190-490 area.Currently it is Category B.

- The Fal Estuary.Oysters Ostrea edulis Abalone Despite being esturine this is a Category A and is consistently in the 80-200 E.coli range.

Results

All per 100g flesh

Jersey

Date Oyster Ecoli Abalone E.coli Mussel E.coli

7/9/09 | 230 | <20 | 230 |

19/10/09 | 330 | <20 | 420 |

9/11/09 | 130 | <20 | 80 |

4/1/10 | 140 | <20 | 80 |

1/3/10 | 790 | 80 | 120 |

28/4/10 | 80 | 0 | 50 |

14/6/10 | 50 | <20 | <20 |

10/9/10 | 230 | 50 | 90 |

Falmouth and Truro Port Health Authority

Date Flat Oyster E.Coli Abalone E.coli

14/7/09 | 90 | 50 |

3/6/09 | 50 | <20 |

5/5/09 | 220 | < 20 |

6/4/09 | 90 | <20 |

5/1/10 | 170 | 50 |

Interpretation.

Both sites were sampled and analysed using competent authority sampling and reference public health laboratories,.

The results can be interpreted in an approximate manner (the <20 results etc precludes total accuracy but reflects how these data are given to the farmer) as such a simplistic ratio can be derived.

Oysters C.gigas 9 Mussels 5 Oysters O.edulis 4 Abalone H.tub 1

This ratio appears consistent across a wide range of contaminant levels but should only be used as an indicative guide. That said the potential for an A Category result bearing in mind the environment required for good quality growth and survival , namely good quality ,

full salinity seawater with full oxygenation at all times is almost ensured. Norovirus /Ecoli contamination exercise.

A challenge test was undertaken using oysters (C.gigas) Mussels (M.edulis) and Ormers (Haliotis tuberculata) derived from Jersey Sea Farms and delivered to Integrin Ltd, Oban a UKAS accredited laboratory. Integrin is a highly experienced laboratory and has access to standardised Norovirus and appropriate handling facilities.

The experimental animals were received in good condition and were allowed 5 days to stabilise in 10C clean seawater.

At the start of a 48 hour period a standardised loading of Ecoli and GII norovirus was introduced . Samples were taken initally after half an hour extending to 15 hours as the experiment ended . With E.coli the inital results were noisy' due surface contaminations but soon settled into a distinct set of curves.Once settled after 48 hours the shellfish registered

Abalone 21 Ecoli/100g

Mussels 394 Ecoli/100g

Oysters 1949 Ecoli/100g

These figures are generally consistent with the results of actual production areas .

GII norovirus was not detected in any species at the start of the experiment. Virus was accumulated very quickly by oysters, reaching a plateau within 5 hours and possibly as quickly as 30mins.

Mussels also accumulated very quickly but peaked much later at around 9hours and concentrations were much lower than in oysters.

Abalone appeared to accumulate much more slowly and no significant amounts of virus could be detected until 9hours exposure. Thereafter levels approached, but may have been marginally lower than those detected in mussels.

Note that, following convention, E.coli levels are reported as log10 number per 100g, whereas norovirus is reported as number per gram.

Note also that the copy numbers are derived from standard curves and QPCR is at it's least accurate towards the limit of detection, and at close to the limit it's not uncommon to see discrepancies between repeats of around 3 cycles, which corresponds to an order of magnitude. This is particularly evident when working with difficult matrices like shellfish. This explains how the tables contain negative logs: where the standard curve suggests that one copy should correspond to, say Ct of 44, then a Ct of 47 would indicate 0.1 copies. In reality this is just noise and it's unwise to rely too heavily on the quantification below 10 copies.

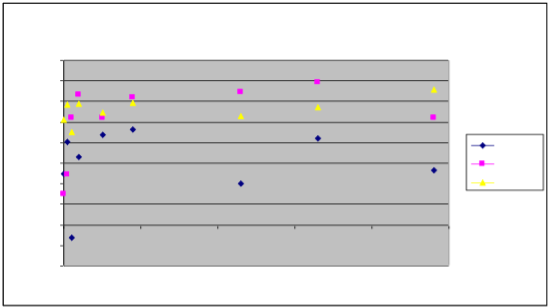

Ecoli

Ecoli

4

3.5

3

2.5

2 abalone

1.5 mussels 1 oysters

0.5

0

-0.5 0 10 20 30 40 50

-1

time

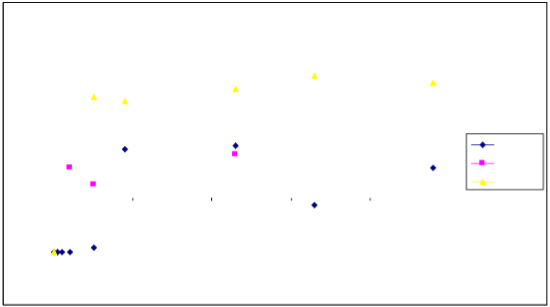

NLV GII

NLV GII

4 3 2 1 0 -1 -2

| ||

| ||

|

| |

|

| |

0 10 20 30 40 5 | ||

| ||

abalone mussels oysters

time

Log10 copy numbers per gram of tissue (norovirus) or 100g tissue (E.coli)

Norovirus GII

T (h) abalone mussels oysters

0 -1.62 -1.62 -1.62 0.5 -1.62 1.13 3.07 1 -1.62 -0.76 3.01 2 -1.62 0.83 2.06 5 -1.48 0.35 2.91 9 1.38 1.73 2.77 23 1.50 1.24 3.14 33 -0.24 0.68 3.54 48 0.85 1.01 3.33

E.coli

abalone mussels oysters

1.25 0.75 2.57

2.02 1.21 2.93 -0.31 2.61 2.26 1.65 3.17 2.93 2.19 2.59 2.73 2.33 3.10 2.96 1.01 3.23 2.65 2.10 3.47 2.85 1.34 2.60 3.29

Results Table 3.

Appendix 1

List of relevant EC regulations regarding public health safety of molluscs.

Regulations that relate to live and processed abalone .

Council Directive 91/492/EEC Establishing health conditions for the production and marketing of live molluscs.

Council Directive 97/61/EC Amending 91/492/EEC

Council Directive 79/923/EEC On the quality required for shellfish waters.

Regulation 854/2004 Controls on the organisation of offical rules on the production of animal products for consumption.

Regulation 853/2004 Laying down specific hygiene rules for food of animal origin.

Commission Decision 93/51/EEC Microbiological criteria on cooked molluscs (included in 91/492/EEC

Council Decision 1999/313/EC On reference Laboratories

Council Decision 93/383/EEC On reference laboratories for biotoxins. Commission Decision 96/77/EC PSP levels.

Commission Decision 2002/225/EC Detailed rules on marine biotoxins in molluscs

Commission Decision 2002/226/EC Establishing special health checks for the harvesting of molluscs with ASP

Commission Regulation 466/2001 Cd,Hg and Pb levels in molluscs

Commission Directive 2001/22/EC and 2001/182/EC laying down methods for sampling and analysis Pb, Cd, Hg and 3-MCPD

Council Regulation 2375 /2001 Sets dioxin TEQ levels

Council Directive 96/23/EC Residues in animal products.

Commission Decision 98/179/EC Sampling and monitoring rules. Commission Decision 98/536/EC List of reference labs.

Commission Decision 2001/66/EC Third country import list. Commission 2002/336/EC Third country residue sampling requirements.

Commission Decision 92/92/EEC Dispatch and purification centre requirements and derogations.

Commission Decision 93/25/EEC Purification treatments. Commission Regulation 2065/2001 general fish product traceability.

This is not meant to be an exhaustive list but an indication of requirements that will apply to a farm producing live abalone for human consumption.

The Following documents are attached for direct reference. Annex I

The Proposed Draft Standard for Fresh/Live Abalone CX/FFP of the WHO/FAO Food Standards Codex Committee which is due for finalisation in October 2009.

AnnexII

INTRODUCTION TO THE ANALYIS OF REGULATIONS OF INTEREST TO PUBLIC HEALTH SAFETY OF MOLLUSCS AND MOLLUSC PRODUCTS H.Lupin

Annex III

EC 854/2004

Annex IV

EC2073 Microbiological Standards for Foodstuffs Annex V

Risk Profiling of Norovirus.

Annex VI

New Zealand Seafood HACCP guidelines manual.