The official version of this document can be found via the PDF button.

The below content has been automatically generated from the original PDF and some formatting may have been lost, therefore it should not be relied upon to extract citations or propose amendments.

States of Jersey

Bellozanne Sewage Treatment Works Best Available Technology Report May 2012

Prepared for:

States of Jersey

Transport and Technical Services PO Box 412

States Offices

South Hill

St Hellier

JE4 8UX

Prepared By:

Enpure

Enpure House Woodgate Business Park Kettlewood Drive Birmingham

B32 3DB

T +44 (0)121 2519000 F +44 (0)121 2519111

EXECUTIVE SUMMARY.1 1.0 INTRODUCTION...2 2.0 CONSENT ISSUES.2

- SECONDARY TREATMENT...3

- ACTIVATED SLUDGE PROCESS......4

- EXTENDED AERATION .....5

- SEQUENCING BATCH REACTOR (SBR)....5

- MEMBRANE BIOREACTORS (MBRs).6

- DEEP SHAFT PROCESS..6

- MOVING BED BIOREACTORS (MBBR)..7

- TRICKLING FILTERS.8

- BIOLOGICAL AERATED FILTERS (BAFs)9

- SUMMARY OF PROCESSES CONSIDERED.10

- PROPOSED SECONDARY TREATMENT ALTERNATIVES.10

- CARBONACEOUS (BOD) AND NITRIFICATION (AMMONIA) REMOVAL PLANT.11

- TOTAL NITROGEN PLANT.11

- RECOMMENDED CONCEPT DESIGN...12

5.0 CONCLUSION..13

6.0 BELLOZANNE PHASED CONSTRUCTION..13

Executive Summary

The sewage treatment plant at Bellozanne currently does not achieve the required discharge consent and suffers from extensive biological foaming, a consequence of which is poor removal of suspended solids and lower bacteriological kill from the UV disinfection process.

In order to address the above issue, a review is being carried out so as to ascertain what the options are surrounding the required discharge consent from the works and to determine the process options available to achieve these consents. Clearly the process design and selected technologies are largely driven by the consent standard required.

Sensitive waters are designated under the Urban Waste Water Directive where more stringent treatment is required to protect the aquatic environment of the receiving water. This can be enclosed bays with the risk of nutrient growth, or designated shell fisheries where much cleaner water is required in terms of bacteriological quality. Inland the nutrient to be controlled is phosphorus but in saline conditions this is nitrogen.

Populations above 15000 to 100,000 are subject to a 15 mg/l Total Nitrogen (TN) limit in the event of the receiving water body being designated as sensitive. For populations above 100,000 the TN limit is 10 mg/l. Generally these limits are applied as annual averages.

Bellozanne has a population equivalent below the 100,000 value in winter but above in the summer months. Should the receiving water be designated as being sensitive, a TN standard of 10 mg/l in the summer months and 15 mg/l in the winter months could be applied. Denitrification is very temperature dependent and therefore the winter consent standard applied to the works will affect the size and cost of the treatment plant required.

Striking the correct balance between environmental and health benefits can be achieved by a more robust treatment process which will include establishing an optimum' length of outfall based on the assimilative capacity of the receiving waters.

For example, a plant designed to achieve a TN standard will be much larger and have much higher energy costs than a plant designed to achieve the Urban Waste Water Treatment Directive standard for a non sensitive receiving water i.e. 25 mg/l BOD, 35 mg/l SS. The Marcon report suggests that for a relatively small increase in the length of the discharge pipe the impact of the discharge on the receiving water can be significantly reduced. If this is the case a far more robust treatment process with lower energy usage and complexity can be considered.

The preferred treatment process regardless of consent standard required is the activated sludge process. This encompasses a variety of mechanisms and processes that use dissolve oxygen to promote the growth of biological floc. Activated sludge is a robust well known technology that is familiar to the operators at Bellozanne thus minimising any training that would be required. It also provides a high degree of flexibility of operation to allow for the variation in summer/ winter influent conditions. Should a carbonaceous removal (BOD standard) or nitrifying (ammonia standard) be required then a variation of the activated sludge process known as the Inclined Bubble Aeration (IBA) would be proposed. This provides simplicity of control whilst avoiding over aeration which is common on standard systems and thereby significantly reduces the overall energy consumption. The IBA system cycles between aerobic and anoxic periods and therefore a degree of denitrification is achieved. However to achieve a 15 mg/l or 10 mg/l TN standard a large anoxic zone and a large recycle from the aerobic to the anoxic zone are required. Due to these design requirements a more conventional layout based on separate anoxic and aerobic stages is required.

This report reviews the best available treatment options for Bellozanne STW and having examined the advantages and disadvantages of each process, proposes a preferred way forward and layout for each of the consent standards that are under discussion.

1.0 Introduction

The purpose of this report is to review the best available technologies together with economic and environmental considerations to achieve the consent standards currently being discussed for Bellozanne STW taking into account the limited land area available.

The current sewage treatment plant does not meet the consent standard required. The current works and problems encountered are covered in Operation Strategy Report of 14th

May 2011. This Best Available Technology Review report does not cover the current plant operation or performance but concentrates on the technologies available for a new sewage treatment works based on the various consent standards currently being discussed.

Sewage treatment consists of Preliminary, Primary and Secondary Treatment and where required tertiary treatment is installed as a polishing stage.

Preliminary treatment concerns the removal of debris, rags, FOGs (fats, oils and greases) and grit. Primary treatment concerns the removal of readily settleable solids in order to reduce the load on the biological treatment. Both stages will cover the same unit processes regardless of the effluent quality consent being considered and have been discussed in the Treatment Process Review' prepared by Grontmij in September 2009. They are not therefore covered any further in this report.

The main biological stage in a sewage treatment plant is the secondary treatment. This is really the heart of the process and will change considerably depending upon the effluent standard required. Three consent standards are considered in the report for Bellozanne STW: -

- Carbonaceous (BOD) only

- Carbonaceous and nitrification (BODand ammonia removal)

- Carbonaceous, nitrification and denitrification (BOD, ammonia and Total Nitrogen (TN) removal). TN standard of 15 mg/l or 10 mg/l on an average basis. (Note: There is the possibility of having seasonal consents whereby a tighter TN standard of 10 mg/l is achieved in the summer months and 15mg/l in the winter months)

It should be noted that as the discharge consent gets tighter the size and cost of the sewage treatment works increases in capital cost and usually in operating cost as well.

In addition the energy consumption in treating the sewage influent to a low BOD and ammonia concentration is high. Process design can optimise the energy consumed but clearly the biology drives the energy requirement and is dependant upon the consent required.

2.0 Consent Issues

The key international best practice legislations associated with discharges of wastewater to marine environments are the European Union Urban Wastewater Directive (UWWTD) 91/271/EEC and the Bathing Waters Directive 76/160/EEC. Also, the Water Framework Directive is the most extensive and important piece of legislation to emerge from the EU for the water environment. It requires that all inland and coastal waters achieve "good" environmental status by 2015.

Sensitive waters are designated under the Urban Waste Water Directive where more stringent treatment is required to protect the aquatic environment of the receiving water. This can be enclosed bays with the risk of nutrient growth, or designated shell fisheries where much cleaner water is required in terms of bacteriological quality. Inland the nutrient to be controlled is Phosphorus but in saline conditions this is Nitrogen.

Populations above 15,000 and up to 100,000 are subject to a 15 mg/l Total Nitrogen (TN) limit in the event of the receiving water body being designated as sensitive. For populations above 100,000 the TN limit is 10 mg/l. Generally these limits are applied as annual averages.

In the UK because of the significant tidal currents, there are few sites with TN limits. The only ones of significance are:-

• Budds Farm of Southern Water - This is Portsmouth's WwTW and serves a population of 350,000 and as such is required to meet a TN standard of 10 mg/l. The receiving watercourse is a slow moving estuarine creek which is a sensitive water.

• Ballynacor in Northern Ireland serves a population of 135,000 where a TN limit of 15 has to be met. The discharge is into Lough Neigh which though large in surface area is shallow.

• Ballyrickard in Northern Ireland serves a population of over 100,000 where a TN limit of 10 mg/l is required. The discharge is into Strangford Lough which is a SSSI. The discharge is particularly sensitive as the Lough is a commercial shell fishery and a bacteriological standard has been set on the final effluent.

• Armagh in Northern Ireland serves a population of 45,000 where a TN limit of 15 mg/l has been applied.

The solution adopted at all four sites has been conventional Activated Sludge with a much larger anoxic zone than usual and mixed liquor recycle for all flows up to 4 x DWF. In addition there are several works with a Population Equivalent (PE) of less than 50,000 that have been designed based on the activated sludge process to achieve a 15 mg/l TN annual average.

As far as Bellozanne STW is concerned the winter population is estimated to be below the 100,000 Population Equivalent (PE) value but the summer population exceeds this value. Should St Aubin's Bay be considered to be a sensitive receiving water and a TN standard be envisaged as being necessary then there is a strong argument for having seasonal consents. As detailed above nitrification/ denitrification are temperature sensitive and therefore a seasonal consent would affect the size of treatment plant required.

If St Aubin's Bay is not assumed to be Sensitive', treatment of discharged effluent from the Bellozanne STW shall be in accordance with Article 4 of the UWWTD (91/271/EEC) and the discharge shall satisfy the requirements of Annex I.B as shown in Table 1 and summarised as follows:

• Biochemical Oxygen Demand (BOD5) - 25 mg/l

• Chemical Oxygen Demand (COD) - 125 mg/l

• Total Suspended Solids - 35 mg/l

- Secondary Treatment

The secondary treatment stage is normally classified as either a fixed film or suspended growth process and there are processes that use a combination of the two.

A suspended growth process is one in which the micro-organisms responsible for the treatment are maintained in suspension within the liquid in what is termed activated sludge. Suspended growth systems provide considerable flexibility of operation and in the case of conventional systems, have a proven track record. For the plant at Bellozanne the suspended growth systems considered are conventional activated sludge process, Sequential Batch Reactors (SBRs), Membrane Bioreactors (MBRs) and Deep Shaft Process.

Fixed or Attached growth processes are ones in which the micro-organisms are attached to some inert medium such as rocks, blast furnace slag or specially designed plastic materials. Fixed film systems include Moving Bed Bioreactor (MBBR), Trickling Filters for carbonaceous removal, carbonaceous and ammonia removal or just ammonia removal, Biological Aerated Filters (BAF), Rotating Biological Contactors and Submerged Aerated Filters (SAF). The latter two systems are not considered as they are not suitable for a population as high as that of Bellozanne STW. Moving Bed Bioreactor (MBBR), Trickling Filters and BAFs are discussed further in sections 3.6, 3.7 and 3.8 respectively.

Fixed film systems are robust but tend not to have the same flexibility of operation that an activated sludge plant has. Furthermore, due to the low retention times on some fixed film systems breakthrough of ammonia can occur where high peak concentrations are experienced.

The process options considered for secondary treatment for a plant the size of Bellozanne STW are reviewed below.

- Activated Sludge Process

The conventional activated sludge process (ASP) is the most widely used secondary treatment process. It is a suspended growth process utilising dispersed bacteria in the shape of flocs.

Organic material in the sewage is utilised under aerobic conditions when waste water is brought into contact with a dense microbial population.

Organic material in the sewage is utilised under aerobic conditions when waste water is brought into contact with a dense microbial population.

The particulate and colloidal material is first absorbed on to the microbial floc while the soluble material is utilised immediately. Part of the organic matter is oxidised to carbon dioxide and water while the remainder is assimilated into new cell growth (biomass). A portion of the microbial floc is wasted in what is known as Surplus Activated Sludge (SAS) in

order to keep the concentration within the treatment process at the required level.

The three principal configurations of ASP can be classified according to their hydraulic flow characteristics as follows: -

Batch (Sequential Batch Reactor) Plug Flow

Completely Mixed

The batch system is covered in the section on Sequential Batch Reactors (SBRs) below.

Plug flow and completely mixed systems comprise a selector zone, an aeration tank and settlement tanks. Should a Total Nitrogen (TN) standard be required then an anoxic zone is also required.

In the aeration tank the settled sewage and the flow of returned activated sludge (RAS) are mixed and aerated. The air input to the process supplies the oxygen required for respiration for micro-organisms and in most systems to keep mixed liquor suspended solids in suspension.

After the period of aeration in the aeration tank the mixed liquor passes to a final settlement tank. Here the activated sludge flocs settle to the bottom of the tank from where the sludge is continuously withdrawn and returned to the inlet of the aeration tank or removed from the system as SAS. The supernatant liquor now purified passes over the outlet weir.

The ASP process can be designed to treat any of the consent standards currently being discussed although the layout and control systems will differ. Should a BOD standard or a BOD and ammonia standard be required then an Inclined Bubble Aeration Design as described in 4.1 would be the preferred option. Should a TN standard be required then the high recycle requirement would mean that the system would require modification and a more complex control implemented.

The size of the secondary treatment stage increases substantially as the effluent standard becomes tighter. For example the secondary treatment volume to achieve an ammonia standard will be approximately three times that of a plant to achieve BOD only. A plant that has an additional TN standard will be larger still (4 to 5 times that of a BOD removal only system), the extent depending upon the actual TN standard required.

This is the most reliable process in terms of robustness and flexibility of the options considered.

- Extended Aeration

Extended aeration is similar to item 3.1 above except that no primary tanks are utilised. This has advantages on smaller works and results in a slightly lower land take than conventional activated sludge. However it is not an option for Bellozanne as the primary sludge is needed for the anaerobic digestion plant to be stable in operation. Extended aeration also has a higher energy input than conventional activated sludge.

Extended aeration is similar to item 3.1 above except that no primary tanks are utilised. This has advantages on smaller works and results in a slightly lower land take than conventional activated sludge. However it is not an option for Bellozanne as the primary sludge is needed for the anaerobic digestion plant to be stable in operation. Extended aeration also has a higher energy input than conventional activated sludge.

- Sequencing Batch Reactor (SBR)

The process has been covered in detail in the Technical Note prepared by Grontmij on SBR in April 2010. It is not proposed therefore to go into further detail

The process has been covered in detail in the Technical Note prepared by Grontmij on SBR in April 2010. It is not proposed therefore to go into further detail  here.

here.

Enpure have designed and built SBRs to achieve both carbonaceous and nitrification consents. SBRs that encompass denitrification have also been designed but this is only carried out to recover some of the nitrate and reduce the aeration required. They are not designed to achieve a TN standard as part of the consent. The choice of SBR is driven by very low land availability and it should be noted that in the author's opinion it would be unreliable in terms of meeting a tight TN standard. An SBR would not therefore be a realistic option should a TN standard be in place at Bellozanne and whilst it could reliably provide the treatment required for ammonia or a BOD standards, the plant is far more difficult to control than a conventional activated sludge plant.

For sewage treatment, SBR size tends to be driven by hydraulics rather than biology on a sewage system particularly if the sewage is dilute. This means that it can be bigger than it needs to be for the biological load which obviously has a knock on cost implication and can mean that control of the biological system is difficult.

SBRs can be designed for continuous inflow or batch inflow. Both systems have their advantages and disadvantages but for a true batch system there is a requirement for a balancing tank in order to balance the flows out of the plant and prevent pulses of flow passing out of the works. The size of balancing tank required after the SBRs is dependant upon the instantaneous flow rate as indicated in the consent standard.

SBRs can be designed for continuous inflow or batch inflow. Both systems have their advantages and disadvantages but for a true batch system there is a requirement for a balancing tank in order to balance the flows out of the plant and prevent pulses of flow passing out of the works. The size of balancing tank required after the SBRs is dependant upon the instantaneous flow rate as indicated in the consent standard.

The complexity of control of the SBR system and lack of robustness of an SBR designed to achieve a TN standard would mean that it would not be considered as a preferred option.

Reasons for not selecting SBR at Bellozanne: -

1 Complex control systems

2 Not as robust for TN standard as conventional activated sludge.

- Membrane Bioreactors (MBRs)

MBRs combine activated sludge treatment with a membrane liquid-solid separation process. The membrane component uses low pressure micro-filtration or ultra filtration membranes and eliminates the need for clarification and tertiary filtration. The membranes are either immersed within the aeration tank or a separate membrane tank is provided. The latter design ensures easier maintenance and cleaning of the membranes but has a higher capital cost. One of the key benefits of a membrane bioreactor system is that it effectively overcomes the limitations associated with poor settling of sludge in conventional ASP processes. The technology permits bioreactor operation with considerably higher MLSS concentrations than conventional ASP systems, which are limited by sludge settling. The process is typically operated at MLSS in the range of 8000 to 12000 mg/l, whereas conventional ASPs are operated in the range of 2000 to 3500 mg/l. The elevated biomass concentration in the membrane bioreactor process allows for the very effective removal of both soluble and particulate biodegradable materials at higher loading rates. Thus, increased sludge retention times, usually exceeding 15

days, ensure complete nitrification even in cold

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() weather.

weather.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() The cost of building and operating a MBR is

The cost of building and operating a MBR is ![]() higher than a conventional wastewater treatment

higher than a conventional wastewater treatment ![]() plant. The small footprint of MBR systems, and

plant. The small footprint of MBR systems, and ![]() the high quality effluent, makes them particularly

the high quality effluent, makes them particularly ![]() useful for water reuse applications.

useful for water reuse applications.

There are numerous examples of industrial effluent treatment of high strength waste low volume

effluents using the MBR approach. However, although examples of municipal wastewater treatment by MBR exist, these are mostly small. The largest MBR plant in the UK is in Buxton (Severn Trent Water) with a PE of 32,000. Generally it has only been used where a small footprint plant is required or where a massive and rapid increase in load has to be accommodated to maintain consent.

Reasons for not selecting MBR at Bellozanne: -

1 High capital cost

2 High maintenance costs/ operations involvement to keep membranes clean. Potential

problem with blinding of membrane.

3 Sewage treatment plants to date are on smaller PE of approximately 35,000.

- Deep Shaft Process

The DeepShaft activated sludge system was invented by ICI as a spin-off from the manufacture of Pruteen, which is a microbial protein grown on methanol. It is a high rate activated sludge system which is able to run at higher mixed liquor concentrations and at loading rates 5 to 10 times greater than conventional systems. The aeration requirement is also reduced by the nature of the process because it has a greater efficiency of oxygen transfer into solution.

The system works by drilling a shaft typically 40 to 100m deep, using techniques from the oil industry. Raw sewage enters a holding tank where it is mixed with return activated sludge. This mixture of raw sewage and return activated sludge is passed down the centre of the shaft and re-circulates back up the outside with the aid of compressed air. This typically takes between 2 to 6 minutes and the sewage is circulated around 20 to 40 times prior to discharge. After treatment the effluent is clarified by flotation or sedimentation of solids.

The principal advantages are that no primary settlement stage is required and its footprint is relatively small. However at the Bellozanne site the first advantage can not be realised as primary tanks are required in the future design to provide primary sludge for reliable operation of the anaerobic digestion process.

An additional process would also be required for nitrification/ denitrification as only carbonaceous removal is achieved by the Deep Shaft process. Its use in the UK has been limited to two works which primarily treat industrial effluents and one where space is severely restricted.

The process has been covered in detail in the Technical Note prepared by Grontmij on Deep Shaft ASP Reactors, April 2010. It is not proposed therefore to go into further detail here.

Reasons for not selecting Deep Shaft Process at Bellozanne: -

1 High capital cost of drilling and lining the deep shaft depending upon the underlying

geological conditions

2 Better on high strength industrial effluents, >500mg/l BOD, not low concentration sewage

flows (typically 200 to 250 mg/l BOD).

3 High rate process achieving carbonaceous (BOD removal) only. No nitrification or

denitrification is achieved. Difficult to upgrade system to TN standard.

4 Foaming issues experienced due to high DO levels within the biomass

5 High pressure blowers required – high maintenance costs.

6 Sludge characteristics can make treatment difficult. Toothpaste type consistency of

dewatered sludge causes stacking problems.

7 No primary tanks therefore only biological sludge is produced. This is very difficult if not

impossible to digest reliably and will certainly cause problems with the sludge treatment process (anaerobic digestion) on the site.

- Moving Bed Bioreactor (MBBR)

The MBBR process is a continuously operating biofilm reactor with low headloss where the biomass grows on small carrier elements that move along with the water in the reactor. The mixing required is provided by coarse bubble aeration that also supplies the aeration input needed to maintain the required dissolved oxygen content in the reactor.

The biofilm carrier elements are maintained within the reactor by a screen which is placed at the reactor outlet. The agitation within the vessel is arranged such that the carrier elements are constantly being moved away from this sieve screen.

Enpure have designed and installed numerous MBBR plants and MBBR/ ASP hybrids. These do provide a high level of treatment on a small footprint area but tend to be higher capital and operating costs than a straight activated sludge plant. Certainly for a TN standard the capital cost would be significantly higher. Settlement of the sludge can be problematic in conventional settlement tanks and DAF has been

Enpure have designed and installed numerous MBBR plants and MBBR/ ASP hybrids. These do provide a high level of treatment on a small footprint area but tend to be higher capital and operating costs than a straight activated sludge plant. Certainly for a TN standard the capital cost would be significantly higher. Settlement of the sludge can be problematic in conventional settlement tanks and DAF has been

utilised on some sites with a lower throughput although operating costs are higher. This is an option for Bellozanne STW particularly for a carbonaceous removal only plant, but for a nitrifying/ denitrifying plant it would not be the preferred option. DO levels are high leading to potential foaming and filamentous issues and an additional carbon source may well be required for the denitrification stage. In the activated sludge process the denitrification process is situated at the front of the

utilised on some sites with a lower throughput although operating costs are higher. This is an option for Bellozanne STW particularly for a carbonaceous removal only plant, but for a nitrifying/ denitrifying plant it would not be the preferred option. DO levels are high leading to potential foaming and filamentous issues and an additional carbon source may well be required for the denitrification stage. In the activated sludge process the denitrification process is situated at the front of the

works and some of the suspended biomass is recycled to the front of the works such that the raw sewage can be used as the carbon source. For a fixed film system such as an MBBR, recycling of biomass is not an option so the denitrification stage is positioned at the end as a polishing stage so raw sewage can clearly not be used. A carbon source such as methanol is therefore required which will increase the operating cost of the plant.

Reasons for not selecting MBBR at Bellozanne: -

1 High capital cost

2 High DO levels in biofilm reactor if nitrification required, leading to higher operational

costs than conventional activated sludge.

3 Suspended solids distribution in effluent can lead to poor UV transmissivity and therefore

poor disinfection.

- Trickling Filters

Trickling filters have been used to provide biological wastewater treatment for nearly 100

years. Modern trickling filters have a bed of media

years. Modern trickling filters have a bed of media

(mineral or plastic) over which the wastewater is

continuously distributed. Air is provided by ventilation at

the base of the filters and percolates naturally through

the bed. Most filters are of the low rate type and are

around 1.8m deep. The media grows a natural culture of

bacteria which breaks down the Biological Oxygen

Demand (BOD) with higher organisms e.g. protozoa,

worms and fly larvae grazing on the film formed on the

media. The grazing organisms ensure that the sludge production is less than other secondary processes. Nitrification of ammonia to nitrate takes place in the lower part of the filter and is carried out by autotrophic organisms which are slow growing.

Lower ammonia levels require filters of greater than 1.8m depth and very often filters in series are provided to achieve the required loading rates. Either way trickling filters are susceptible to high peaks in ammonia passing through the system and causing high spikes in the effluent. They are however simple to operate and are highly dependable for carbonaceous removal and ammonia removal providing a reasonably smooth influent concentration is experienced.

The effluent produced by filters has to be settled in tanks of a similar construction to primary tanks. Most humus tanks, as they are termed, are of radial or upward flow type. The sludge is removed at regular intervals from the bottom of the tanks and the overflow passes forward. The sludge is usually pumped to the primary tank feed to be co-settled with the primary sludge because on its own it is thin and difficult to thicken.

Trickling filters are classified by their hydraulic or organic loading rates. As the effluent standard gets tighter, a lower organic loading rate is required and the trickling filter gets bigger. A single stage of trickling filters would be required for carbonaceous removal whereas for tight ammonia standards frequently two-stage filters in series are required. The first would remove the carbonaceous material and the second stage would act as a nitrification stage. As with the MBBR and other fixed film processes, for a total nitrogen system an external carbon source would be required to be added to the denitrification stage.

Compliance with ammonia standards of 5 mg/l can be achieved but compliance with an ammonia standard of 3 mg/l is uncertain. In addition any spikes in the influent ammonia load will pass straight through the biological filter and cause consent failure. Enpure have had problems achieving a 5mg/l ammonia standard with nitrifying filters due to the high peak load seen when a cattle market was held for example. Several UK water companies installed plastic media biological filters to improve nitrification at less stringent ammonia consents but these have not generally been a success. They need a high degree of recirculation at low flows and are prone to shed biomass under high flow conditions. This can lead to SS consent failures followed by ammonia compliance problems until the lost biomass re-grows. Nitrifying biological filters with plastic media are also known to lose performance during cold weather.

Compliance with ammonia standards of 5 mg/l can be achieved but compliance with an ammonia standard of 3 mg/l is uncertain. In addition any spikes in the influent ammonia load will pass straight through the biological filter and cause consent failure. Enpure have had problems achieving a 5mg/l ammonia standard with nitrifying filters due to the high peak load seen when a cattle market was held for example. Several UK water companies installed plastic media biological filters to improve nitrification at less stringent ammonia consents but these have not generally been a success. They need a high degree of recirculation at low flows and are prone to shed biomass under high flow conditions. This can lead to SS consent failures followed by ammonia compliance problems until the lost biomass re-grows. Nitrifying biological filters with plastic media are also known to lose performance during cold weather.

Reasons for not selecting Trickling Filters at Bellozanne: -

1 Large land area requirement,

2 Not robust for tight ammonia standards.

3 Achievement of TN standard complex.

4 Suspended solids distribution in effluent can lead to poor UV transmissivity and therefore

poor disinfection.

- Biological aerated filters (BAFs)

BAFs are groups of tanks which provide self-contained aeration and, to a varying degree, solid separation treatment of sewage. Depending on the supplier of the proprietary process, the process may be upward or downward flow. The media is about 6mm in diameter and tends to be ignited shales or natural pumice type material.

Good performance from a BAF unit requires good upstream process performance in order to provide a good influent. The BAF process is particularly suitable for providing tertiary polishing treatment for discharge consents with tight ammonia limits. However this requires a separate secondary treatment stage and results in a high cost solution.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() BAF discharge characteristics may not be acceptable as a result of

BAF discharge characteristics may not be acceptable as a result of ![]() surges after backwash, which may also affect downstream processes,

surges after backwash, which may also affect downstream processes, ![]() particularly UV disinfection. Particle size distribution of the discharge

particularly UV disinfection. Particle size distribution of the discharge ![]() may also affect UV disinfection. Some BAF manufacturers have a

may also affect UV disinfection. Some BAF manufacturers have a ![]() maturation cycle after backwash to limit the effects of surge. Flow

maturation cycle after backwash to limit the effects of surge. Flow ![]() smoothing by attenuation downstream is permissible. BAFs can also

smoothing by attenuation downstream is permissible. BAFs can also ![]() be operated for denitrification with an additional carbon source, namely

be operated for denitrification with an additional carbon source, namely ![]() glycerol.

glycerol.

Reasons for not selecting BAFs at Bellozanne: -

1 High capital cost

2 Difficult to get robust carbonaceous oxidation and nitrification.

3 Achievement of TN standard complex.

4 Suspended solids distribution in effluent can lead to poor UV transmissivity and therefore

poor disinfection.

- Summary of Processes Considered

Process | Footprint | Energy Demand | Relative Sludge Production | Achievable Treatment Standard | Complexity |

Traditional ASP | Depends upon standard required | Average, lower than MBR or extended | Average | High | Established technology, robust and simple |

Extended Aeration | Large | High | Low | high | Established technology, robust and simple |

SBR | Small | Average | Average | Carbonaceous and nitrification reliable. | Complex control |

MBR | Small, no FSTs but always nitrifying so large ASP | High | Low | Very high | High maintenance |

Deep Shaft | Small | High | High | Low | Operational issues |

MBBR | Compact, depends on consent standard | Average, high if nitrifiying | Low | High but cost increases substantially | Simple control |

Trickling Filter | Very large | Low | Low | Good, can be suspect to ammonia spikes and solids affect UV disinfection. | Simple |

BAF | Medium | Average | Low | High, can have issues with particle size and UV disinfection | Complex control |

- Proposed Secondary Treatment Alternatives

The preferred process for the treatment plant at Bellozanne is the activated sludge process as presented in Section 3.1. The reasons for this are: -

- Established process with proven track record on all three standards being considered as noted in the table below.

- High flexibility of operation for seasonal variation in incoming load.

- Ease of control and operation, particularly if the Inclined Bubble Aeration, IBA, process (detailed in section 4.1) is utilised. IBAis suitable for carbonaceous and nitrification. Denitrification would require modification to the process.

- Operators' familiarity with the process.

The table below shows the comparative volume of each of the treatment stages required within the secondary treatment stage for each of the consent types being considered. In order to compare the volume required for each stage, the numbers in the table below depict the equivalent volume ratio required ie the aerobic zone for the Nitrification, Ammonia Standard requires three times the volume that is required for the carbonaceous removal.

| Carbonaceous Removal Only | Nitrification, Ammonia Standard | Denitrification, TN Standard |

Selector Zone | Minimal Volume | Minimal Volume | Minimal Volume |

Anoxic Zone | Not Required | Not Required | 1.5 - 2 Unit volume |

Aerobic Zone | 1 Unit volume | 3 Unit volumes | 3 Unit volumes |

The size and approximate land area required for each of the three consent standards detailed in the above table has been examined and is discussed further below.

- Carbonaceous (BOD) Removal and Nitrification (Ammonia Removal)

The plant design for these two systems will be similar albeit the aeration part of the process will be approximately three times bigger for the plant with the ammonia consent. An ammonia standard will also result in a much higher energy input due to higher aeration requirements.

The activated sludge system would be based upon the Inclined Bubble Aeration (IBA) system where the air to the activated sludge tanks is switched on and off to control to a set point range (typically 1 to 3 mg/l). This has the following advantages: -

The activated sludge system would be based upon the Inclined Bubble Aeration (IBA) system where the air to the activated sludge tanks is switched on and off to control to a set point range (typically 1 to 3 mg/l). This has the following advantages: -

Lower Capex - This negates the need for inverter driven blowers and control valves thus ensuring a simple and robust control system.

Reduced energy usage - Flow inducers within the aeration lanes for keeping the solids in suspension mean that the blowers can be switched off when the DO level reaches a high set point thus ensuring that over-aeration is not realised when low loads are entering the works.

Over Aeration Minimised - Over aeration typically happens at night time on sewage plants with a normal' diurnal variation and can result in over aeration causing process issues such as filamentous growth. This happens on conventional plants as the blowers provide the air for mixing as well as treatment and this can exceed the DO required by the biomass thus resulting in high DO levels. In the IBA system the on/off control prevents this from happening.

Enpure have installed the IBA system on many sites with excellent results and a corresponding reduction in overall energy use due to the control system utilised.

Both plants will fit within the preferred allocated area within the site boundary. This means

that the existing works will continue to receive and treat the incoming flows whilst the new

sewage treatment works is being built. The relative site layout is shown in section 6.0, Figure 1.

A plant that achieves a good nitrified effluent will obviously reduce the oxygen demand of the sewage plant effluent. It will however result in a larger secondary treatment phase and higher oxygen input into the treatment plant itself. Environmental factors within St Aubin's Bay would have to balanced against the higher energy input required in the STW in order to assess the least overall environmental impact.

A plant that achieves a good nitrified effluent will obviously reduce the oxygen demand of the sewage plant effluent. It will however result in a larger secondary treatment phase and higher oxygen input into the treatment plant itself. Environmental factors within St Aubin's Bay would have to balanced against the higher energy input required in the STW in order to assess the least overall environmental impact.

- Total Nitrogen Plant

The design of this system will be very dependent upon the Total Nitrogen (TN) standard required and the minimum design temperature used. ie summer/ winter consents.

To take the first of these items, the plant will vary significantly between a TN of 10 mg/l and 15 mg/l in the following areas: -

- The 10 mg/l standard will require a much higher recirculation rate from the back end of the works to the front end of the aeration tanks. This is required to reduce the nitrates to nitrogen and will mean higher energy costs than that realised in a 15 mg/l standard.

- The anoxic zone will be much larger in order to remove the additional nitrate.

- There are also reports of low BOD concentrations in winter entering theworks. This may affect theworks ability to denitrify without an additional carbon source. This would need further investigation should a TN standard be required.

The design temperature will also have a large effect on the size of treatment works required. Both nitrification and denitrification are very temperature sensitive. To this end a plant designed to achieve a certain standard throughout the year would be larger than one that was designed to achieve a seasonal consent (summer/winter). There are many plants in Europe that are designed to achieve a BOD and ammonia standard in the winter months and then a denitrification standard in the summer months only. Traditional winter design temperature

used for plant design within the UK is between 8 and 10oC. However the temperature of the mixed liquor suspended solids (the contents of the aeration tank) have been measured at

Bellozanne and are around 13 to 16oC in winter and normally around 19oC or higher in summer. There is an argument therefore for using a winter temperature of 12oC for the plant design should a winter consent be required. This difference would have an effect upon the size of plant required.

If St Aubin's Bay is deemed to be Sensitive', treatment of discharged effluent from the Bellozanne STW at present shall be in accordance with Article 4 of the UWWTD (91/271/EEC) and the discharge shall satisfy the requirements of Annex I.B as shown in Table 2 with respect to annual average total nitrogen of no more than 10 mg/l for a PE of more than 100,000 and no more than 15 mg/l for a PE of less than 100,000 (70 – 80% reduction in relation to the load of the influent).

Based on the current and projected PE, it is clear that the connected PE to Bellozanne STW is less than 100,000 during winter months and there is a case to be argued for seasonal consents if there is a need to agree a total nitrogen standard in the future. On this basis, consideration can be given for total nitrogen in the winter months of no more than 15 mg/l and in the summer months (May to October, inclusive) of no more than 10 mg/l.

Based on the above consents the secondary treatment stage of the plant will be approximately 4.5 to 5 times the size of a carbonaceous removal only system and therefore carries a significant increase in capital cost.

The use of an anoxic zone to recover some alkalinity and save energy by using the fixed oxygen in the nitrate to cover some of the BOD demand is sound and can be incorporated within the design without a TN standard. Indeed many plants that are designed to achieve ammonia consents incorporate an anoxic zone of around 30 minute's retention to do just that. However by fixing a TN standard to the design, the control and operation of the plant becomes more complex both in terms of its biology and its control systems.

- Recommended Concept Design

The proposed solution is designed to fulfil the following requirements: -

- plant flexibility and ease of operation,

- the ability to cater for future loads and future discharge consents,

- ease of phased construction such that the appropriate solution is achieved at the appropriate time and the plant can be expanded without affecting the discharge consent,

- consideration of carbon and overall energy use.

To this end it is recommended that the outfall is extended to below the low water mark to achieve better dispersion into the receiving water. It is understood from a previous study that by increasing the outfall pipe the impact of the discharge on the receiving water can be significantly reduced.

This would allow a phased construction with the initial plant being designed to achieve a BOD, SS standard only. Plant design would ensure that the plant could be expanded, without affecting the carbonaceous discharge consent standard, to achieve future nitrification and/or TN standards if required after the outfall extension. This ensures that the plant with the lowest whole life cost and energy use is installed initially thus minimising the carbon and energy use.

5.0 Conclusion

Based on the Best Available Technology review, our findings can be summarised as follows:

- A conventional activated sludge plant to achieve a BOD standard with conventional primary tanks can fit on the proposed area for the new works. This provides a robust plant and the system is known to the operators and process control simple.

- A plant using conventional primary tanks and a secondary treatment process for BOD and ammonia removal can fit onthe proposed area for the new works. Energy usage will be higher than item 1 and thenew works will require a greater degree of civil works.

- A plant to achieve a Total Nitrogen standard of10 or 15 mg/l can be fitted onto the site with conventional primary tanks but requires extensive hillside excavation. Again energy consumption is significantly higher than item 1.

- The recommendation is to increase the length of the outfall to below the low tide mark and build a sewage treatment works that allows phased construction. Phase 1 would be designed to achieve carbonaceous removal with further expansion for Phase 2 and 3 should a nitrifying and/or TN standard be required inthe future.

6.0 Bellozanne Phased Construction

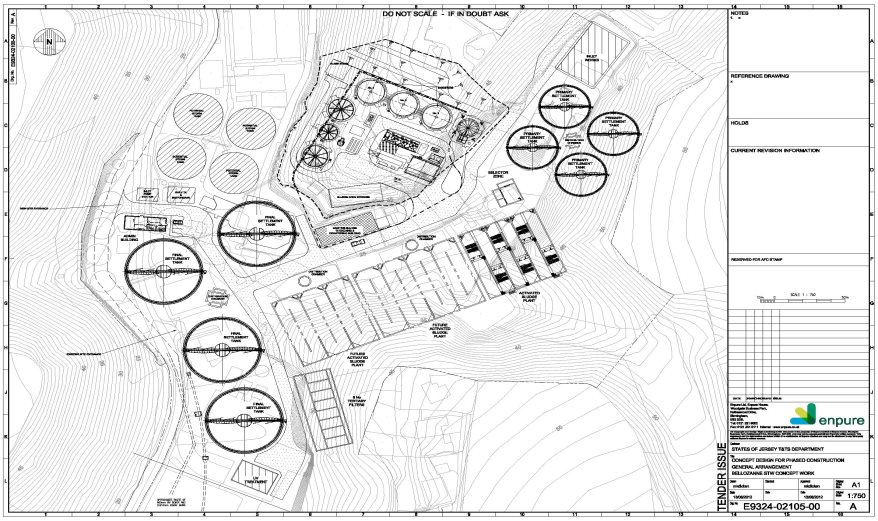

Figure 1 below gives an indication of the proposed site layout for the phased construction under consideration. The initial plant required for carbonaceous treatment is shown in bold and the additional plant required for the possible future ammonia and TN consents in dotted. Initially three activated sludge streams are provided to achieve the carbonaceous removal. A further four streams would be added should a nitrification standard be applied and yet a further three streams are required to give a total of ten streams should a TN standard be applied. A TN standard would also require additional works to allow for the high recycle flow required to remove the nitrate.

![]() Figure 1: Proposed Phased Construction For Bellozanne STW

Figure 1: Proposed Phased Construction For Bellozanne STW

Best Available Technology Review 14